How Do Manufacturers Minimize Magnetic Field Exposure in Electric and Hybrid Cars

While electric and hybrid vehicles are widely recognized for their environmental advantages, there remains a parallel issue that is less visible: exposure to magnetic fields.

Manufacturers have adopted several strategies over the years to address this exposure. These methods vary in effectiveness, cost, and complexity. The following outlines both the conventional and emerging approaches currently applied in vehicle design.

Traditional Methods of Reducing Magnetic Fields

A number of legacy design techniques are commonly used to reduce magnetic field levels within the cabin. These methods offer partial mitigation but often come with trade-offs in performance, weight, or cost.

A number of legacy design techniques are commonly used to reduce magnetic field levels within the cabin. These methods offer partial mitigation but often come with trade-offs in performance, weight, or cost.

1. Shielding

Shielding refers to the use of materials that either absorb or deflect magnetic fields. Comparable to sunglasses that limit incoming light, shielding materials are applied around high-current components (such as battery packs or electrical cables) to limit the spread of magnetic fields into the passenger space.

While effective to a degree, shielding materials are typically dense and heavy. Their application often leads to added vehicle weight, which negatively impacts overall energy efficiency and range, an especially important concern for electric vehicles.

2. Improved Cable Routing

Magnetic field intensity depends heavily on cable placement. By optimizing the routing of high-voltage and current-carrying wires, manufacturers reduce the resultant magnetic field in occupant areas. This method requires precision in layout planning to ensure fields do not concentrate beneath seating areas or around frequently occupied zones.

3. Grounding and Bonding

Grounding provides a return path for electric current, stabilizing voltages and reducing stray electromagnetic emissions. Bonding connects various metallic components within the vehicle, creating a unified reference potential. Together, these practices help suppress field propagation within the cabin environment by ensuring that no unintended current paths develop.

4. Design Adjustments

Engineers may also minimize occupant exposure by relocating high-field sources, such as electric motors or inverters, away from occupied regions of the vehicle. For example, situating these components beneath the hood or rear cargo area can reduce field strength near passenger seats. This spatial separation is often constrained by packaging limitations and design requirements.

Drawbacks of Conventional Approaches

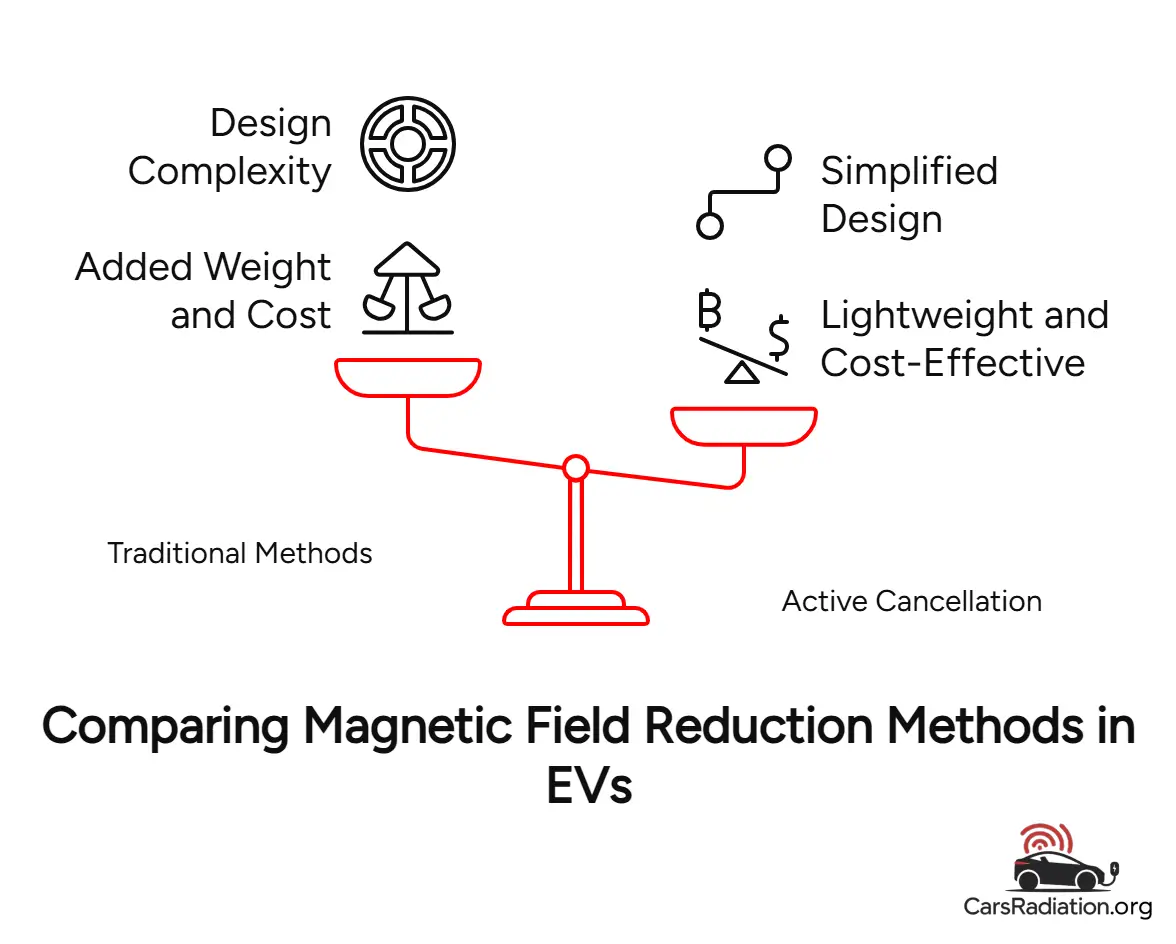

Although traditional solutions play a role in mitigating magnetic field exposure, they often present design, cost, and performance limitations.

Added Weight

Added Weight

Shielding materials are inherently heavy. Their inclusion in the vehicle structure increases overall mass, which in turn lowers driving range and energy efficiency. For electric vehicles in particular, where efficiency is closely linked to weight, this becomes a significant drawback.

Increased Cost

High-grade shielding materials, precision cable layout, and complex bonding structures introduce considerable cost in the manufacturing process. These costs are frequently passed on to the consumer, making such vehicles less accessible to price-sensitive markets.

Design Complexity

Each of these methods (shielding, routing, grounding, and component placement) introduces additional layers of complexity in vehicle architecture. Achieving a balance between field mitigation, mechanical design constraints, and cabin ergonomics requires significant engineering effort and often leads to compromise in one or more areas.

What Is Active Cancellation?

An alternative approach, known as active magnetic field cancellation, offers a novel solution. This method draws parallels to noise-canceling headphones: sensors detect incoming signals (in this case, magnetic fields), and the system generates opposing signals that cancel them out in real time.

An alternative approach, known as active magnetic field cancellation, offers a novel solution. This method draws parallels to noise-canceling headphones: sensors detect incoming signals (in this case, magnetic fields), and the system generates opposing signals that cancel them out in real time.

In automotive applications, active cancellation systems detect the existing magnetic fields within the vehicle and produce reverse-polarity fields that effectively neutralize them. This method does not require dense shielding or extensive routing modifications.

One example is the system developed by SafeFields Technologies. Unlike traditional methods, which attempt to contain or divert magnetic fields, active cancellation addresses the issue at its source: to deliver suppression without the added burden of mass or design constraint.

The Promise of Advanced Solutions

While traditional field reduction techniques remain in use, they are limited by the trade-offs inherent in their application. Active cancellation offers a fundamentally different path and targets the problem with minimal impact on system weight, cost, or design.

As this technology matures and sees broader adoption, it could enable electric and hybrid vehicles to maintain their environmental benefits without introducing long-term health uncertainties due to magnetic field exposure. In this context, advanced mitigation solutions represent not only a technical innovation but a necessary evolution in vehicle safety design.